Bay Window Repairs During Fitting of New Windows

This period property in Southfields, South West London had failing bay window masonry. The old sash windows had been removed but fitting of the new windows revealed the bay window was unstable and out of alignment. Without professional structural repairs this would result in the collapse of the bay window masonry.

The Structural Problem

As with many Victorian/Edwardian properties, issues with the bay windows became apparent during the fitting of replacement windows. New box sash windows were being installed but the surrounding masonry was clearly out of alignment. Repairs were necessary before the replacement window work could be fully completed.

This property in London, SW18, had visible cracking and dropping to the front bay window masonry. The bay had lost the internal brickwork support during the removal of the old box sash windows. Cracking of the first floor masonry lintel components and rendered brickwork were clearly visible. The original internal supports at the head of the bay window structure had been removed together with the original box sash windows.

The combination of inadequate restraining, ageing and the removal of the structural supports to the first floor during the replacement of the original window frames left the bay window unstable. Without suitable structural repairs the bay window was in danger of collapse.

The Structural Repair Solution

To reinstate stability, the bay window structure required the internal supports to be reinstated plus reinforcement of the masonry. Temporary supports were installed to the underside of the first floor front bay window masonry lintel. All the debris was removed from the crack and the lintel was lifted into a more level line with the adjacent brickwork.

Bed joint reinforcement beaming, grout tie injection, resin bonded ties, steel lintels and columns and some masonry repairs were all required. The formation of continuous beams within the existing masonry redistributed the upper storey loads to the supporting structure below while also assisting in restraining diagonal cracking and bulging tendencies. A bespoke steel box lintel frame supported on steel box columns was also fixed to the inside of the masonry columns.

The specialist techniques used by Action Wall Ties installed all the stainless steel fixings within the masonry leaving no visible fixings. Once the area had been redecorated the bay window looked as good as new.

AWT provide cost effective structural repairs for a wide range of structural faults including bay window reinforcement, realignment and lintel repairs. We operate not only in SW London but across the whole of London and the South East of England.

Read our frequently asked questions about bay window structural repairs.

To book a time for one of our surveyors to visit your property or to discuss your requirements, call us today on 01227 721255, email us at enquiries@actionwallties.co.uk or use our contact form to get in touch.

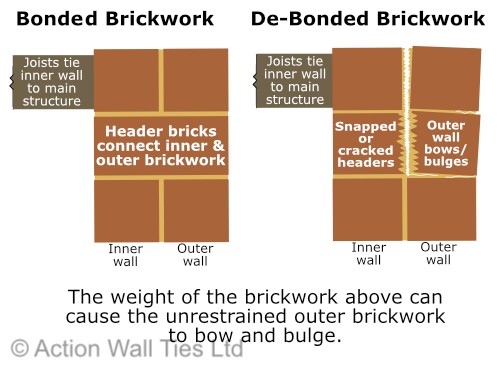

The bulge may have been formed by some de-bonding of the brickwork (or cracking of the headers). It was common practice in buildings of this age for a 9-inch wall to be constructed as two half-brick walls with snapped headers to the external skin to save on expensive facing bricks. This results in a less structurally stable wall, compared to fully bonded brickwork, because the inner and outer skins of the wall are only connected by mortar.

The bulge may have been formed by some de-bonding of the brickwork (or cracking of the headers). It was common practice in buildings of this age for a 9-inch wall to be constructed as two half-brick walls with snapped headers to the external skin to save on expensive facing bricks. This results in a less structurally stable wall, compared to fully bonded brickwork, because the inner and outer skins of the wall are only connected by mortar.