Unstable Period Window Masonry, South West London

This Victorian townhouse in Brixton, London SW9, had severely distorted masonry and large gaps around the top floor windows. The brickwork would collapse without immediate action to repair the structural problems. The defect was also impacting the neighbouring property.

Appropriate structural repairs were urgently required to preserve the period features and the property’s value. Previous attempts to repair the defects by traditional building methods had failed. AWT’s specialist repair techniques allow them to repair period brickwork without visible fixings or slow, messy rebuilding work. This is especially helpful where structural defects are affecting adjoined properties and flats.

The Structural Problem

The visible outward leaning of brickwork and masonry lintels to the front top floor had reached the point of instability. If not addressed rapidly, it would result in the failure and collapse of the masonry. This would then require longer, more disruptive and expensive rebuilding work. It would also cause damage to the property’s period features and impact the resale value.

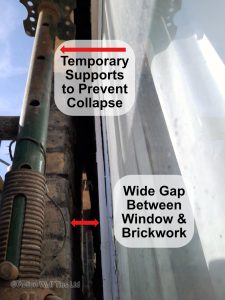

Wide gaps had opened up between the windows as the brickwork bulged outwards. A large gap had also formed above one window and the masonry and lintels were no longer straight.

AWT’s survey found significant outward leaning of the top floor brickwork pier between the windows shared with the adjoining property. The top floor masonry and lintel lintels also showed movement and distortion. AWT diagnosed a progressive structural defect due to ageing and ineffective/inadequate restraining of the masonry.

Previous attempts to repair the structural problem by repointing the area and filling the gaps with mortar had failed to fix the underlying structural issues.

The Structural Solution

Standard building methods tend to provide temporary, cosmetic repairs rather than tackling the root cause of the structural issues. AWT’s specialist knowledge and equipment allow them to remedy masonry defects, add tensile strength and reinstate the integrity of the brickwork. The result is a long-term repair that is not only cost-effective but also requires minimal disruption to residents.

After installing temporary supports to prevent the masonry from collapsing, AWT used specialist structural repair techniques and equipment to restore the structural stability:

- Realignment of Brickwork & Lintels using AWT Designed Realigning Cramping Equipment

- Forming Load Bearing Beams in the Brickwork using Heliforce Bars

- Restraining Bowed Masonry using Thor Restraint Ties

- Reconnecting the Internal Partition Wall using Thor Grout Ties

AWT use precision diamond drilling techniques to install the stainless steel fixing precisely where required. The result is a repair with no visible fixings. The vast majority of the work is completed from the outside of the property, keeping disruption to a minimum.

New, colour-matched mortar is used to restore any areas of disturbed mortar. Stonework, window frames etc are left ready for repainting if required.

Action Wall Ties are specialist structural repair contractors with the skills and experience to repair and restore period properties. AWT works on large and small projects for property owners, structural engineers, architects, project managers and local authorities.

AWT are available in London, Kent, Essex, Surrey and Sussex. To arrange a survey or to discuss project details, please use our contact form, email us or call us on 01227 721 255.