Remedial Wall Ties & Boot Lintel Repairs for 60s/70s House in Thanet

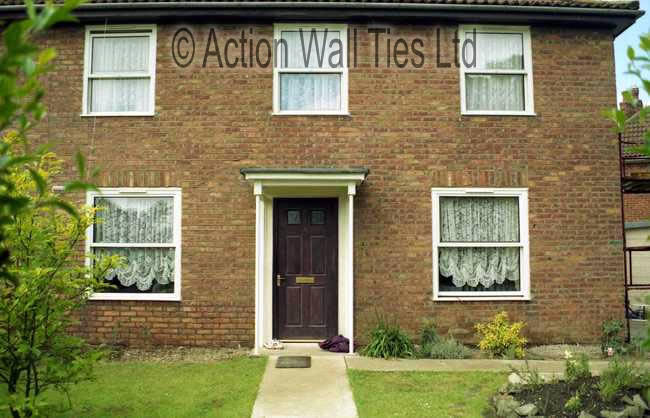

This detached house in Broadstairs, Kent, has a typical 1960s/1970s design and construction. Many similar properties are now developing the same structural problems.

A structural survey of the property indicated issues with the concrete boot lintels and the wall ties. The new owners called in AWT to stabilise the superstructure and protect their investment. Prompt structural repairs prevented the structural defects from causing further damage and avoided more extensive repairs.

The door and window openings were constructed using concrete boot lintels; easily identifiable by the distinctive concrete beams above doors/windows that do not extend beyond the width of the opening. Concrete boot lintels are prone to rotate. This had caused cracking in the internal plaster and cracked, open mortar joints in the external brickwork. The original cavity wall ties were also failing, leaving the outer brick skin unrestrained, and vulnerable to bulging/failure.

Get a Free Estimate

Book your no-obligation, free survey today.

In many cases AWT can provide free advice, without a site visit, based on photos of the structural faults. Send us photos of the defect using our contact form or email us.

The Structural Problem

The property was suffering from 2 main defects that are very common in 1960s/1970s properties; rotating concrete boot lintels and failing wall ties.

Rotation of Boot Lintels:

A fundamental flaw in the installation of concrete boot lintels in 60s/70s properties means that the weight of the heavier brick outer skin is too great for the softer inner blocks to support. The boot lintel rotates, causing gaps to open up, compressing the blocks of the inner wall and allowing the outer brickwork to sag.

The early symptoms of boot lintel problems, as seen below, are cracks in the internal plaster above or radiating from the top corners of doors and windows. It also caused cracking and distortion of the supported brickwork above the doors and windows.

Common symptoms of concrete boot lintel problems:

- Cracks in the internal walls and ceilings above windows/doors

- Warped window/door frames – difficult to open and close

- Cracks in the visible part of the concrete lintel

- Stepped cracks in the brickwork above windows/doors

- Dropping of the brickwork above windows/doors

- Bulging or bowing brickwork above windows/doors

Traditional building repairs – making good the cracks and open joints – treat the symptoms, not the cause. If the rotation continues, serious damage caused by the rotation may result in the necessity to replace the lintels. To avoid further damage to the brickwork, the boot lintels require specialist structural repairs.

Failing Wall Ties & Inadequate Restraint:

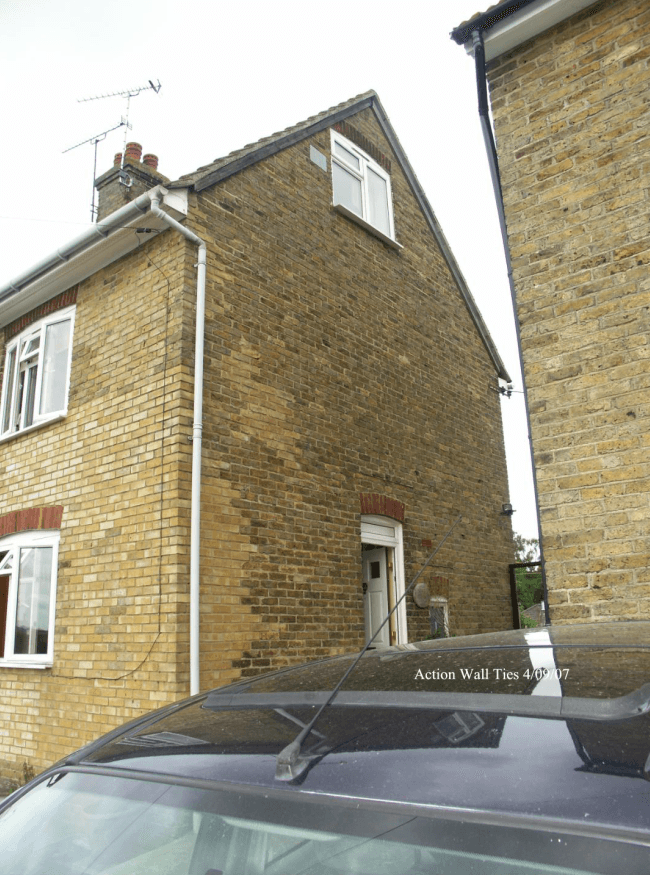

Investigation of the wall ties revealed the existing Wire Butterfly Ties were in varying stages of corrosion and were beyond their useful life. The building had suffered some movement for a prolonged period and was progressive due to a combination of ageing, ineffective and/or inadequate wall tying and restraining plus the effect of rotating fenestration boot lintels all contributing to a lack of structural stiffness.

The progressive corrosion of the existing wall ties left the property vulnerable to vertical and wind loads, especially to large gable and unreturned walls. Instability of the wall will result if the ties corrode away completely, resulting in a need to rebuild the wall. Prompt action to install remedial wall ties will avoid more costly and disruptive repairs in the future.

The Structural Repair Solution

The structural repairs by AWT tackle the root cause of the masonry defects and add tensile strength thus reinstating the brickwork’s integrity.

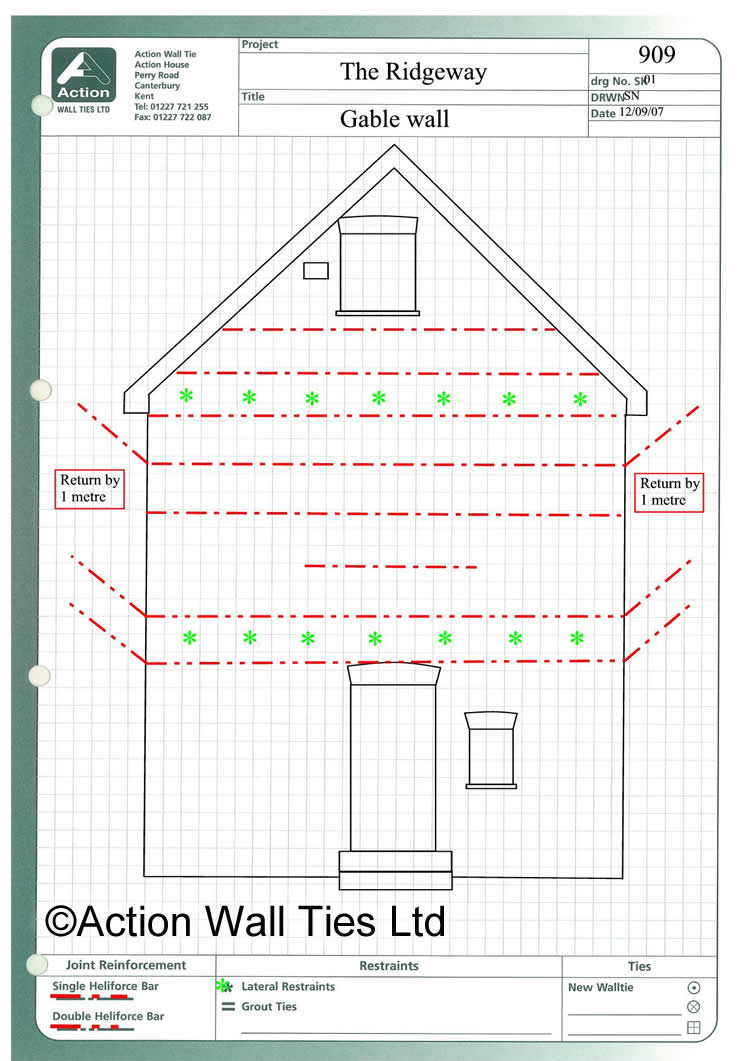

Structural repairs included:

- Bed Joint Reinforcement Beaming

- Fenestration Boot Lintel Treatment

- Grout Tie Injection

- Remedial Wall Ties

The AWT team installed specially developed prop supports to anti-rotate the boot lintel back into place. Specialist diamond drilling techniques were used to drill through the brickwork into the boot lintel and install resin-bonded stainless steel sheer pins.

New pad-stones were installed by providing temporary support to the underside of the lintels, carefully removing sufficient plaster to expose the lintel, cutting out the internal skin and forming a pad-stone to spread the load onto the internal skin. The area was left ready for plastering.

The new wall ties, bed joint reinforcement beaming and grouted ties stabilised the superstructure, reconnecting the inner and outer walls and strengthening the overall structure.

AWT provide cost-effective structural repairs for a wide range of structural problems including failing wall ties and concrete boot lintel problems. We operate not only in Kent but across the whole of London and the South East of England.

To book a time for one of our surveyors to visit your property or to discuss your requirements, call us today on 01227 721255, email us at enquiries@actionwallties.co.uk or use our contact form to get in touch.