Customer Stories

Learn about our previous projects, filter by property type, defect and our solution for each

Learn about our previous projects, filter by property type, defect and our solution for each

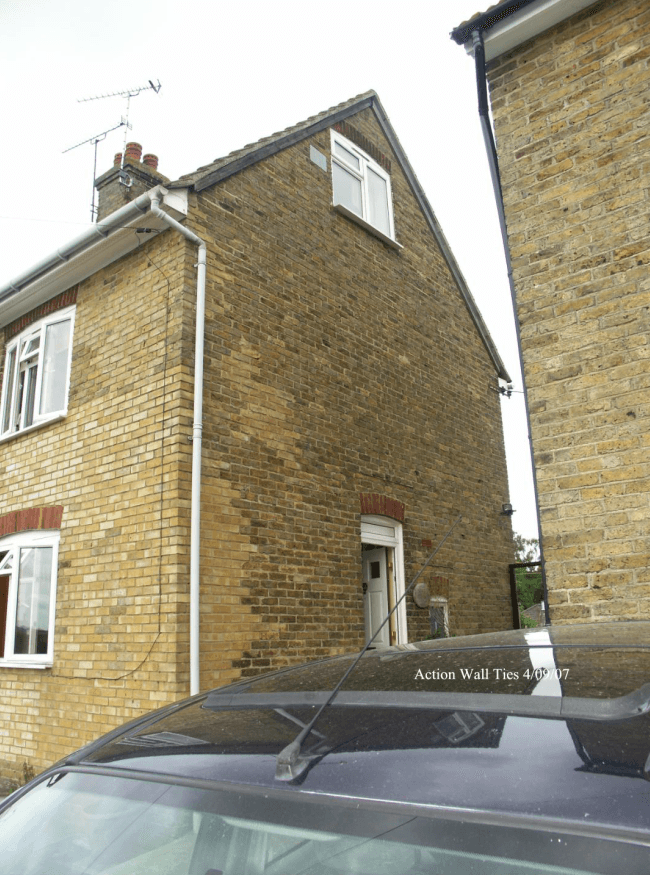

The subject property in Swale, Kent, comprised a 1950s style two-storey semi-detached house of cavity brickwork construction.

The gable wall: The right side gable wall had a visible outward bulge at the centre of the wall at first floor level and significant cracking was noted (no corresponding internal cracking was present). The front elevation external skin was rebuilt after suffering damage in a hurricane. No downward movement at DPC level was noted.

An AWT investigation with a metal detector and an endoscope revealed that the wall ties viewed to the right side gable wall and rear elevations were mild steel vertical twist ties, all in a similar heavily corroded condition and showing signs of de-laminating.

Horizontal cracking, lifting and opening up of joints were noted at irregular intervals on the right side and rear elevations, with corroding ties clearly visible.

Right side elevations: We believed that the movement was progressive, due to ineffective and/or inadequate restraining, and not attributable to significant subsidence.

Wall ties: Our opinion, in accordance with the Building Research Establishment’s recommendations, was that the symptoms noted above were likely to be representative of the majority of the cavity wall ties to the right side, and the main rear elevation suffering from corrosion.

It was believed that the building’s right side and main rear elevation would benefit from remedial wall ties and the isolation of the existing ties.

AWT completed a remedial scheme providing a viable repair by introducing remedial wall ties, isolating the existing ties, then employing bed joint reinforcement beaming, crack stitching and lateral restraints.

Remedial wall ties and isolation of existing ties: Our operatives undertook remedial wall tie treatment to the right side and main rear elevations in accordance with AWT’s wall tie treatment – Generic Repair.

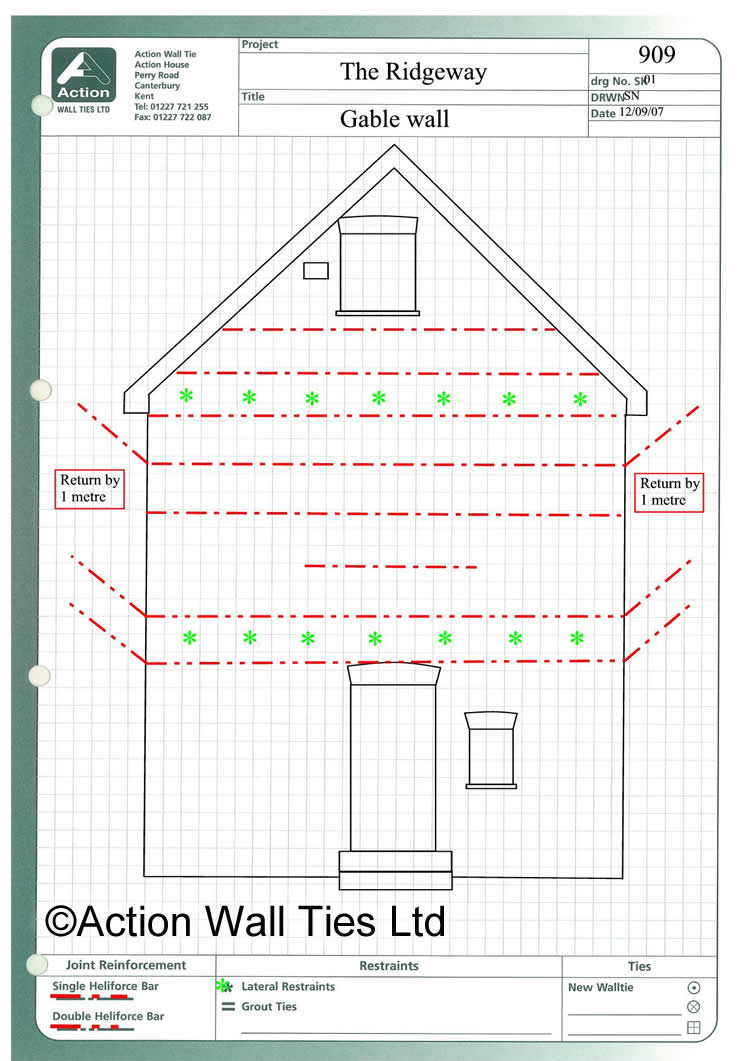

Bed joint reinforcement beaming: The introduction of two rows of twin 8mm stainless steel corded joint reinforcement forming a deep masonry beam – as indicated with red double dotted lines on our proposal plan.

Crack stitching: We stitched localised cracks with the introduction of single 8mm stainless steel corded joint reinforcement – as indicated by red single dotted lines on our proposal.

Lateral restraints: At approximately 900mm centres we drilled for, and screwed directly into alternate timber floor joist’s end grain or into the side grain, 8mm stainless steel lateral restraints into the timber floor and ceiling joists, all resin bonded to the masonry along with corresponding wall ties – as indicated with green stars on our proposal plan.

Make good the pointing: To the cracking schedule for reinforcement listed above, and to areas of weakness to pointing to the right side elevation, we raked out the existing cracked mortar and repaired with new coloured sand and cement mortar to approximately 20mm in depth. AWT operatives are highly skilled in traditional building methods and always attempt to match replacement bricks, pointing styles and mortar colour to be sympathetic with the existing building.

Homeowners, landlords, housing associations and councils across Kent, London, Surrey and Sussex can call on AWT’s experts to repair rusting wall ties and other structural problems. Action Wall Ties (AWT) are specialists in gable wall repairs, masonry reinforcement and repair. We provide professional solutions to a wide variety of structural problems. Contact us on 01227 721 255, or email us.

Our specialist structural repair contractors will be happy to help provide a comprehensive and permanent repair to your structural problems.