Failing Bay Window Support Beam

This beautiful Georgian property in Kent had structural issues with one wing of the property. AWT was called in to assess the distortion of the first-floor windows and ground-floor bay window brickwork and masonry. Cracks had also appeared in the first-floor internal plaster. Like many properties that AWT surveys, there were signs of previous failed repairs.

Our specialist structural repair techniques preserve your property’s period features, which protects its market value.

AWT provided a cost-effective structural repair that minimised disruption to the residents and preserved the property’s period features. To learn more about how AWT can help with structural defects in bay windows, read our Bay Window Structural Repair FAQs.

Unlike traditional builders, AWT can provide targeted, long-term structural repairs without rebuilding work.

The Structural Problem

Bay Window

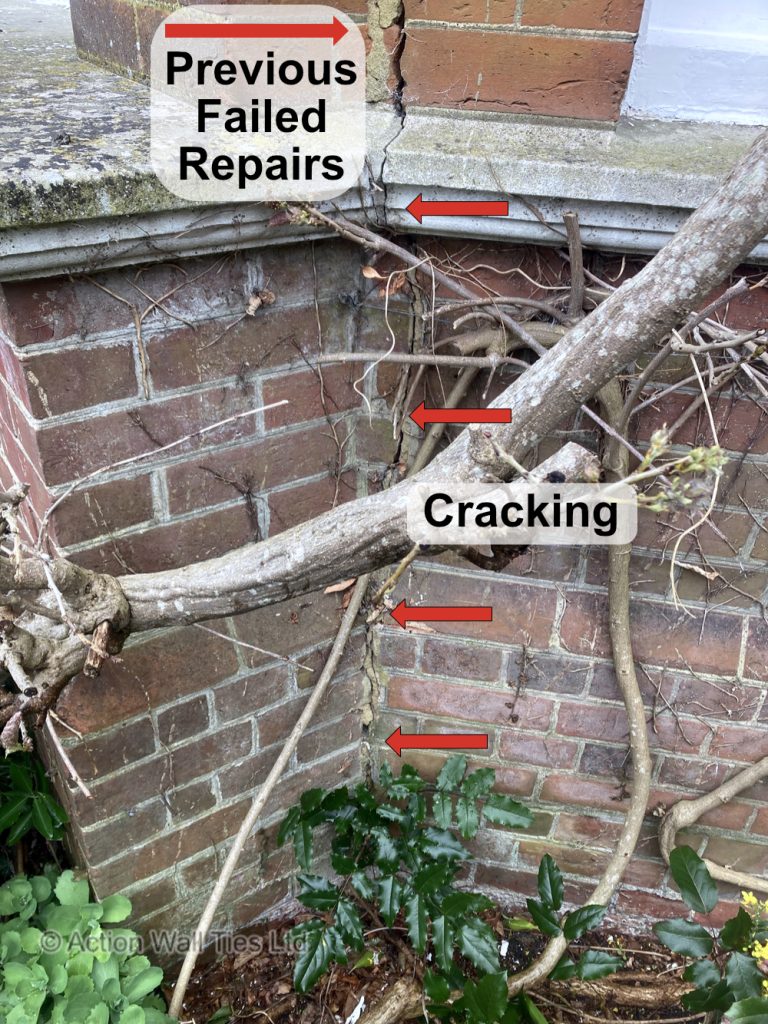

The substantial masonry cornice above the bay window was cracked and showed signs of distortion. Gaps had opened up in the window cill causing cracks in the brickwork below. The brickwork bay window arch was also cracking and dropping.

Like many properties that AWT surveys, there were signs of previous failed repairs.

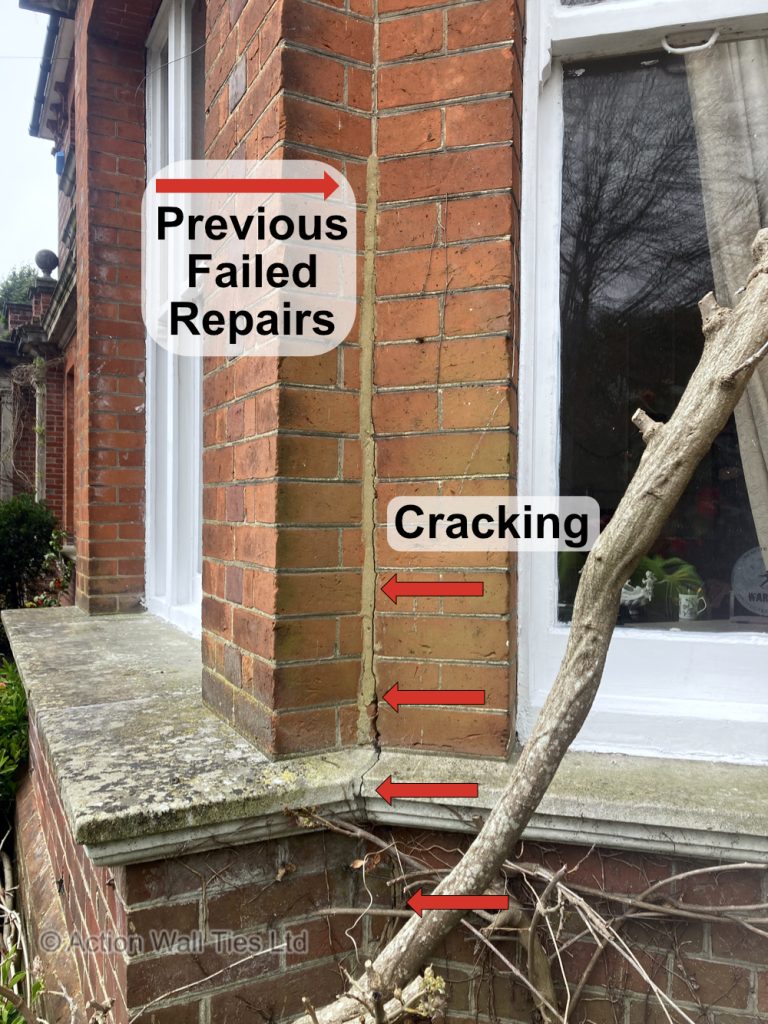

Inspection of the junction between the bay window brickwork and the main elevation revealed cracking and signs of movement. Previous attempts to repair the structural issues using traditional building methods had failed, and the cracks had spread.

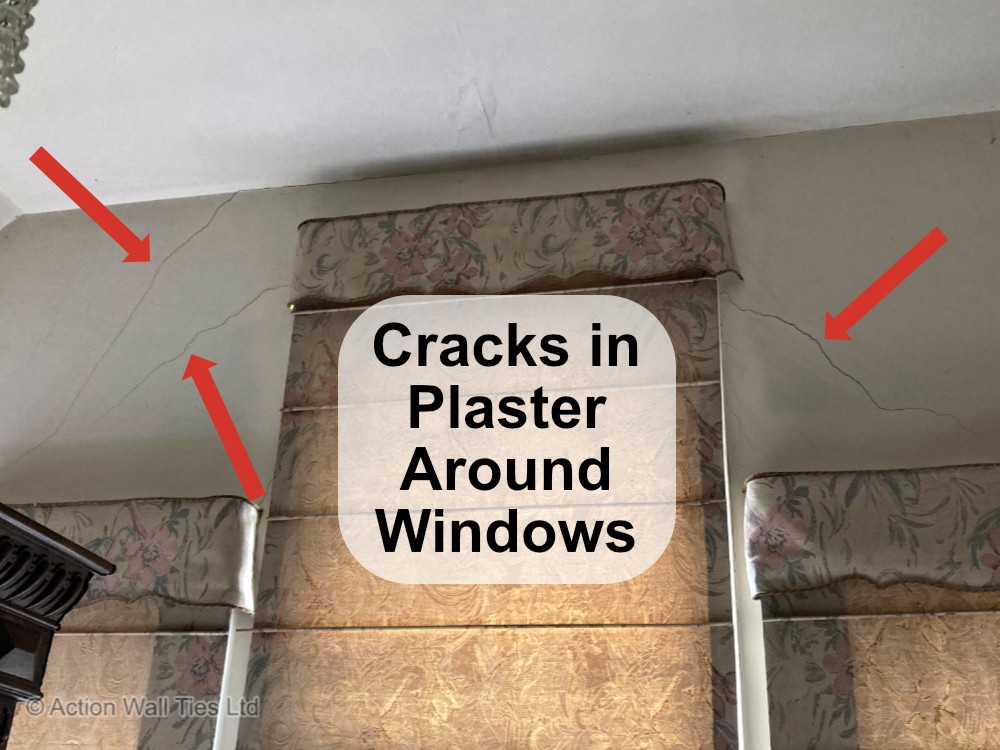

First Floor Windows

The beautiful group of 3 windows is a key feature of the Georgian facade. The significant dropping of the brickwork columns and the semi-circle brickwork arch had left a gap between the brickwork arch and corbeled brickwork above the arch. Without suitable structural repairs, the brick arch could collapse, damaging the period brick and the ornate stone corbel at the top of the arch.

The 2 smaller windows also showed signs of distortion. The brickwork above the windows was cracking and dropping. Inside the property, the plaster around the windows was cracking.

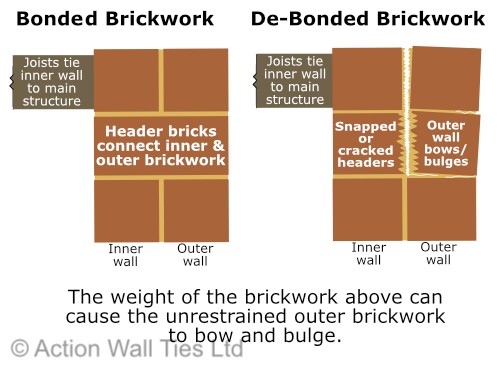

Structural Defects

The timber bressummer support beam over the bay window was overstressed (as are most period beams) and affected by creep, allowing the supported masonry to drop. The masonry required realignment and reinforcement. It also needed reconnecting to the main structure to prevent further movement.

The Structural Solution

AWT provided a set of targeted structural repairs to give a long-term solution without the cost and disruption of rebuilding work. Our specialist structural repair techniques preserve your property’s period features, which protects its market value.

AWT’s special diamond drilling methods developed over many years, and our specialised equipment allows precision diamond drilling to install fixings exactly where they are needed.

The structural repairs included:

- Brickwork Realignment

- Bed Joint Reinforcement Beaming

- Window Lintel Brickwork Arch Repair

- Lateral Restraints

- Precision diamond drilling

- Grout Tie Injection

- Brickwork Repairs

- Concrete Repairs

Action Wall Ties are specialist structural repair contractors with the knowledge and experience required to repair period properties with severe structural defects, such as failed bay window support beams. AWT work with property owners, structural engineers, architects, project managers and local authorities on large and small projects.

AWT are available across London, Kent, Essex, Surrey and Sussex. To arrange a survey or to discuss project details, please use our contact form, email us or call us on 01227 721 255.