Victorian Bay Window & Balcony: Structural Repairs & Restoration

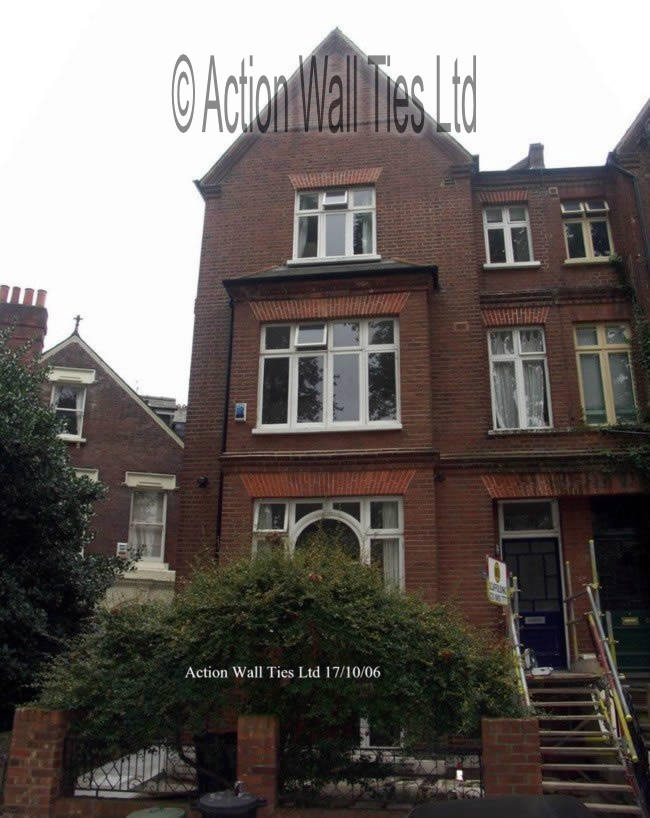

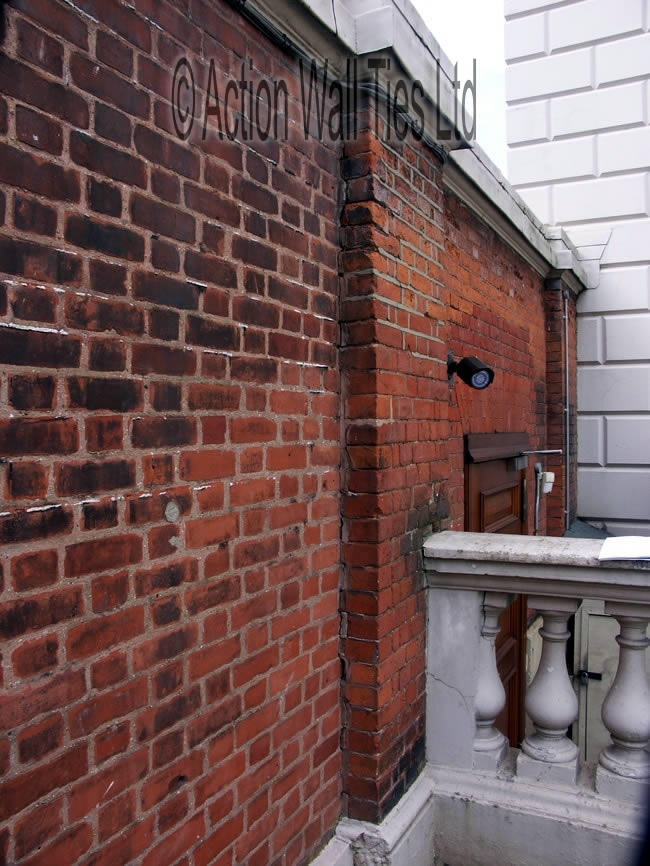

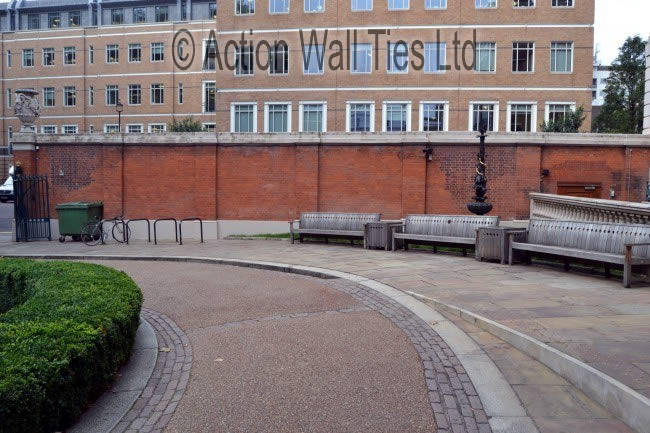

This beautiful example of ornate Victorian architecture in Thanet was at risk of imminent collapse due to severe structural issues. The property had visible significant movement including bowing, cracking, dropping of brickwork arches and bowing columns of the front bay window and to the front elevation.

Several companies had surveyed the problems but none offered any solutions. Previous repairs to the property had tackled the symptoms of the structural defect but had failed to cure the root cause of the problem.

It took just 2 weeks of work for AWT to complete a cost-effective, long-term structural repair. Compared to rebuilding work, the disruption to the residents was minimal.

The Structural Problem

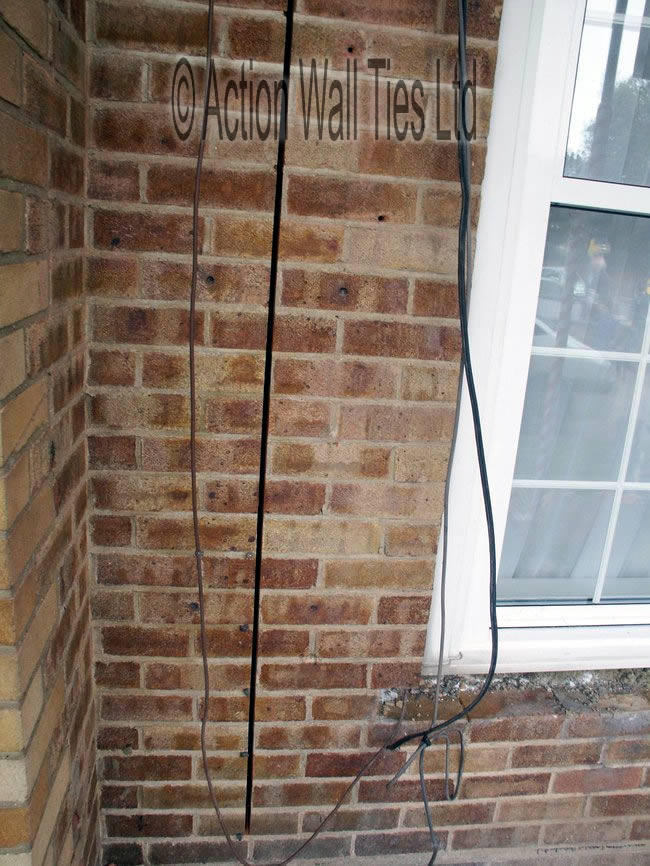

The structural issues with this period property in Thanet, Kent were clearly visible. Wide gaps had opened up between the masonry and the window frames. The structural defect had caused damage from the ground floor bay window columns up to the decorative brickwork panels below the eaves. This entire section of the property was in severe danger of collapse.

Bay Window Issues

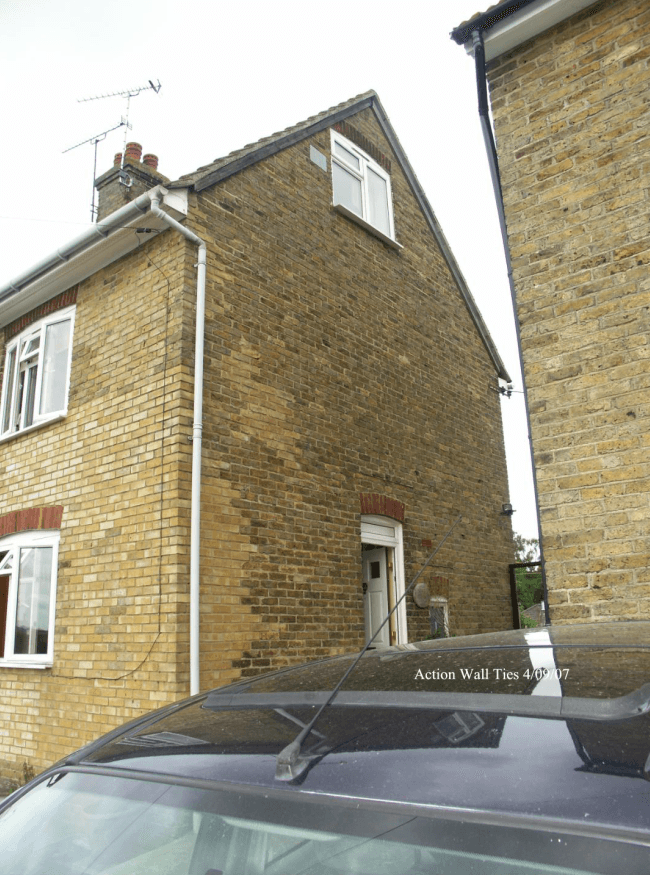

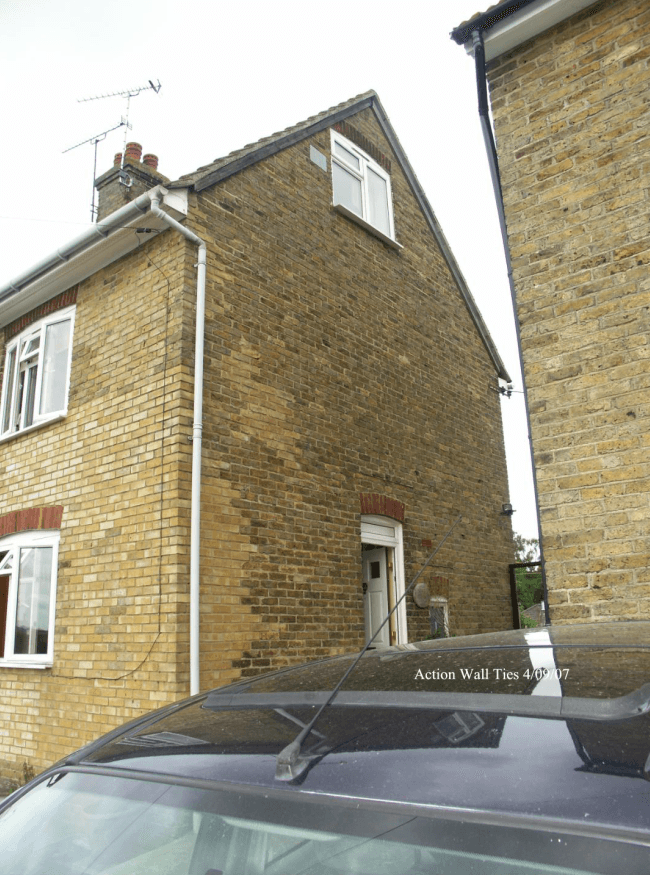

AWT’s inspection of the front bay window found significant distorting movement to the front ground floor causing:

- outward movement

- dropping and cracking of the brickwork arches and stone quoins

- significant outward bowing of brickwork columns beyond the tipping point

First Floor Masonry Issues

Inspection of the front elevational brickwork found signs of distorting movement of the ground floor supporting bressummer beam (over the bay window) causing:

- dropping of the supported main elevational brickwork

- dropping brickwork pier stone quoins

- dropping window arches above the bay window

- inward sloping and cracking of the brickwork above the bay window

As part of previous attempts to halt the movement of the masonry, the bressummer beam over the bay window had been replaced by an old-style RSJ.

Bay & Portico Balcony Issues

The owners also wanted to deal with some aesthetic problems with the bay and portico balcony balustrade’s decorative wrought iron panels and stone top rails. All the panels required refurbishment. The bay window’s stone top rail had been replaced with an unattractive concrete capping. The portico stone top rails were mainly missing. New stones, in keeping with the period features, were needed to complete the restoration.

The Structural Solution

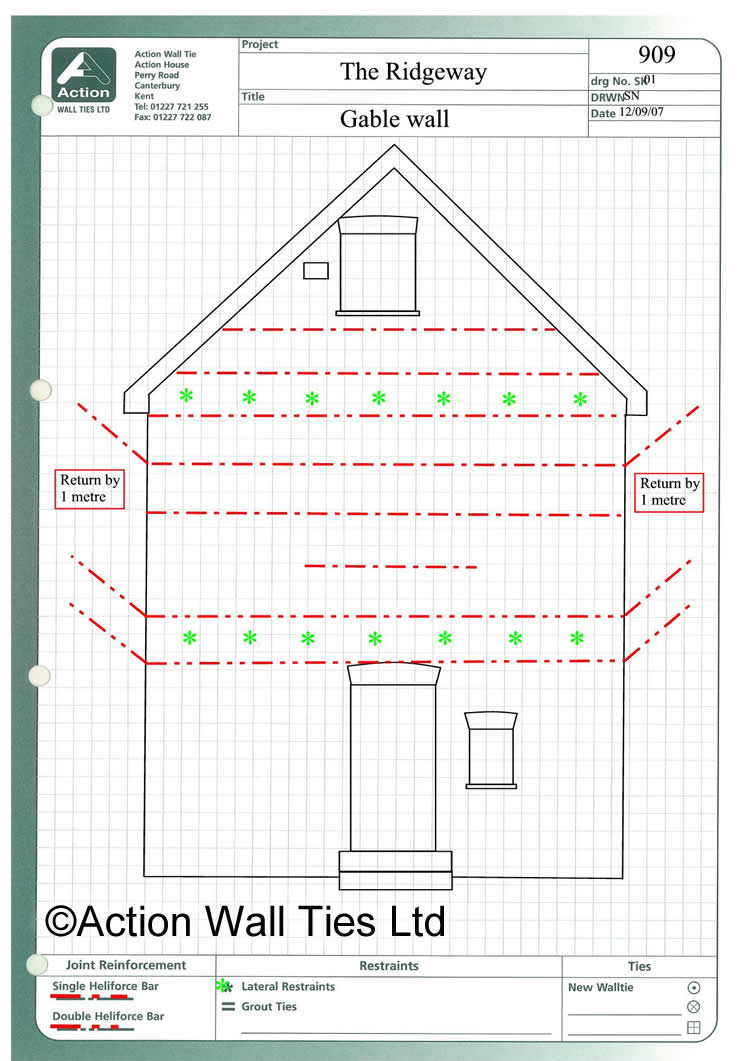

AWT recommended realigning and reinforcing remediation work to the existing brickwork including:

- brickwork realignment

- bed joint reinforcement

- brickwork arch repair

- diamond drilled grouted anchors

- lateral restraints

- grout tie injection

- stonework & brickwork repairs

- addition of fabricated steel spines to the columns

- addition of an internal restraint post to the first floor

This multi-faceted approach reinstates uniformity and provides restraint to the masonry.

AWT also carefully removed the balcony balustrade panels for refurbishment. The lugs were replaced with stainless steel before the panels were grit blasted, powder-coated black and refitted. The brickwork corner piers were rebuilt. Finally, AWT had replacement capping stones cast in a limestone material with stainless steel reinforcing and bedded them in position.

Fast, Cost-effective, Minimal Disruption, Long Term Structural Repairs

Tackling such serious structural issues using traditional building techniques would have required reconstruction and rebuilding of the front of the property. Rebuilding would have been expensive, slow and highly disruptive to the homeowners. Damage to the original bricks and ornate stonework would be inevitable.

In just 2 weeks, AWT’s long-term repairs were completed without major rebuilding work or visible fixings to mar the internal or external period features.

Action Wall Ties are specialist structural repair contractors with the skills and experience required to repair and restore period properties. AWT works on large and small projects for property owners, structural engineers, architects, project managers and local authorities.

AWT are available in Kent, London, Essex, Surrey and Sussex. To arrange a survey or to discuss project details, please use our contact form, email us or call us on 01227 721 255.