Concrete Frame Remedial Works

Inspection of this 9 storey concrete frame tower block revealed serious defects in the previous remedial works by another company. AWT installed remedial head restraints and wall ties to restore structural integrity.

The Structural Problem

This circa 1970s nine storey social housing apartment block in Dagenham that was over clad some two years previously with a polystyrene insulation system, that was deemed unsafe and removed to be replaced with PermaRock mineral Fibre EWI system. AWT was contracted to undertake an intrusive inspection of the wall ties, head restraints and visible concrete elements.

This concrete framed building’s cavity infill walls rely on wall ties to provide a degree of interaction between the two leaves, increasing vertical load and resistance to lateral movement (generally wind load) than two leaves acting separately and head restraints to tie the inner and outer walls to the concrete frame. Sound, correctly installed wall ties and head restraints are vital to the structural stability.

The British Standards Institution and the Building Research Establishment Specification Digest provide clear guidelines for the fitting of wall ties and head restraints in concrete framed buildings. Not only must the appropriate type and size of wall tie and head restraint be fitted but the number of fixings per square metre and the pattern of fixings within the masonry must also be considered.

Our Structural Repair Inspection

The AWT inspection comprised a limited inspection of the existing wall ties by drilling 12mm holes in the outer leaf of the brickwork to view within the cavity using an Endoscope. A metal detector was used to establish the remedial wall tie density and distribution and condition.

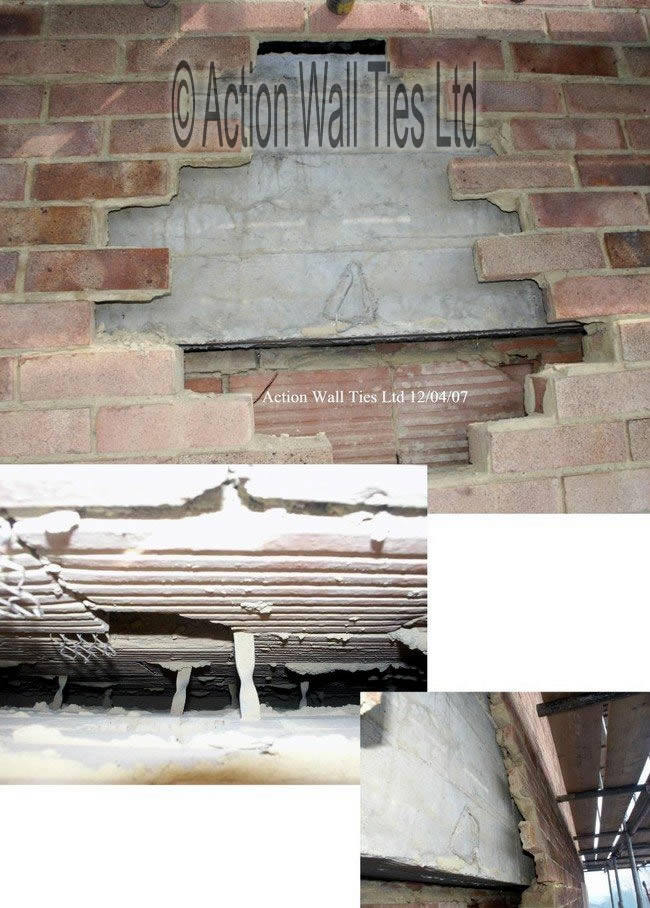

Our inspection revealed the original wire butterfly wall ties were in poor condition and found to be over their useful lifespan. Many of the original wall ties were also incorrectly installed or not embedded at all.

The remedial wall ties installed to replace the original butterfly ties were installed poorly and with insufficient population. Insufficient or incorrectly fitted head restraints dramatically reduce the load bearing capacity of the brickwork. If wall ties are broken, missing or incorrectly fitted this can allow the masonry to bow and crack.

The remedial wall ties were installed in an erratic pattern rather than the recommended pattern for maximum load capacity. The majority of the remedial wall ties had been installed in the mortar bed joints rather than into the bricks. The wrong length of ties had been fitted and insufficiently resin bonded. Many of these wall ties could be removed by hand!

The head restraint fittings were also incorrectly fitted with many being too long and protruding out of the brickwork rather than being securely fixed within the masonry.

The Structural Repair Solution

AWT provided high quality remedial work that is designed to last. Our skilled operatives take pride in their work and are committed to ensuring that every project they complete is safe.

High quality remedial ties were carefully installed in the correct pattern and density. Head restraints were also fitted to restore structural integrity.

AWT provide cost effective, safe remedial repairs to concrete framed buildings throughout London and the South East.

To book a time for one of our surveyors to visit your property, call us today on 01227 721255, email us at enquiries@actionwallties.co.uk or use our contact form to get in touch.