Customer Stories

Learn about our previous projects, filter by property type, defect and our solution for each

Learn about our previous projects, filter by property type, defect and our solution for each

The subject development comprised of five circa 1950/60s high-rise blocks of flats in South West London. The blocks are of concrete frame construction with cavity brickwork infill walls below windows and full height to flank elevations.

The infill cavity brickwork walls were constructed with an external skin of LBC type bricks, 75mm to 95mm cavity, and a hollow clay pot internal skin.

The infill walls were constructed from each concrete floor beam to the underside of the floor beam above with approximately 65mm support to the external brickwork.

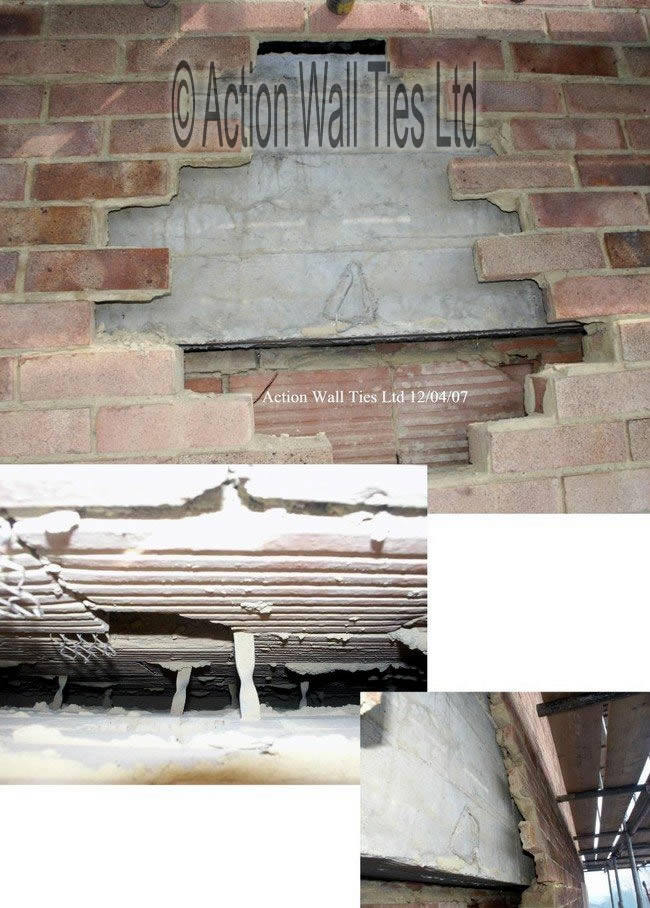

This left 40mm protruding to accommodate six/seven courses of 35mm brick slip bedded onto the floor beam, forming the appearance of continuous brickwork. The bricks have weathered well, with little sign of spalling, though some damaged bricks were noted.

The manufactured brick slips were 35mm thick with a bedding groove to the rear.

The brick slips were bedded down onto the last brick course of the infill wall and onto the face of the concrete beam, with sand and cement mortar up to the first course of the brick wall above (no horizontal soft joints were found).

A cast-in wire butterfly tie was uncovered that had not been bent out and bedded into the mortar as intended. Previous repairs, bulging leaning movement, and hollow and missing brick slips were all noted.

Hollow clay blocks formed the internal skin of the cavity walls constructed in-between the concrete floor/beams and columns.

The wall ties were found to be galvanised vertical twist, generally adequately bedded, clear of building debris, installed to a good pattern and of adequate density.

No head restraints were located with the last row of ties six/seven courses down from the head of the wall. No significant corrosion to the existing ties was noted.

We found that the buildings had generally performed well, including the buildings’ brickwork infill walls, with the exception of the brick slips and the head of the infill walls.

Since the buildings had been completed, the concrete used in their construction had shrunk, the concrete frame had shortened and the bricks’ first irreversible expansion had taken place.

Where brickwork and concrete frame abut these opposing stresses were putting the brickwork in compression, locking in the brickwork to the continuous brick slips to the flank walls.

This effect was further augmented by thermal expansion, especially to the south-facing walls.

Where the walls were not adequately tied the compression force had been released laterally, causing bulging and leaning of the brick slips and the head of the wall down to the first row of effective ties.

Most of the brick slips had become detached from the concrete beam, probably due not only to the compression force described above but to differing movements and poor fixing details. Modern-day standards require a mechanical fixing to each brick slip.

AWT completed a remedial scheme providing a viable repair by rebuilding sections of the brickwork and brick slips, introducing a pattern of mechanical fixings to the brick slips and angled head restraints along with a number of horizontal soft joints.

The gallery below shows the blocks 13 years after work was completed. The quality repairs by AWT are still going strong. In the long term, quality structural repairs provide better value for money than repeated, ineffectual repairs using traditional building methods.

All of our work to low and high rise blocks follows the guidelines provided by the British Standards Institution and the Building Research Establishment Specification Digest.

Action Wall Ties (AWT) are specialists in masonry reinforcement and repair, providing professional solutions to a wide variety of low, mid and high rise block structural problems.

AWT work with councils, housing associations, project managers and architects across London, Kent, Surrey & Sussex.Contact us on 01227 721 255, or email us.

Our specialist structural repair contractors will be happy to help provide a comprehensive and permanent repair to your structural problems.