Fixing Cracking Above Concrete Boot Lintels

Concrete boot lintels to window openings were in common use in the 1970s and have the unique appearance of a visible one course high concrete toe that appears not to have any bearing onto the adjacent brickwork (i.e. the visible concrete toe is in between the brickwork reveals).

Get a Free Estimate

Book your no-obligation, free survey today.

In many cases AWT can provide free advice, without a site visit, based on photos of the structural faults. Send us photos of the defect using our contact form or email us.

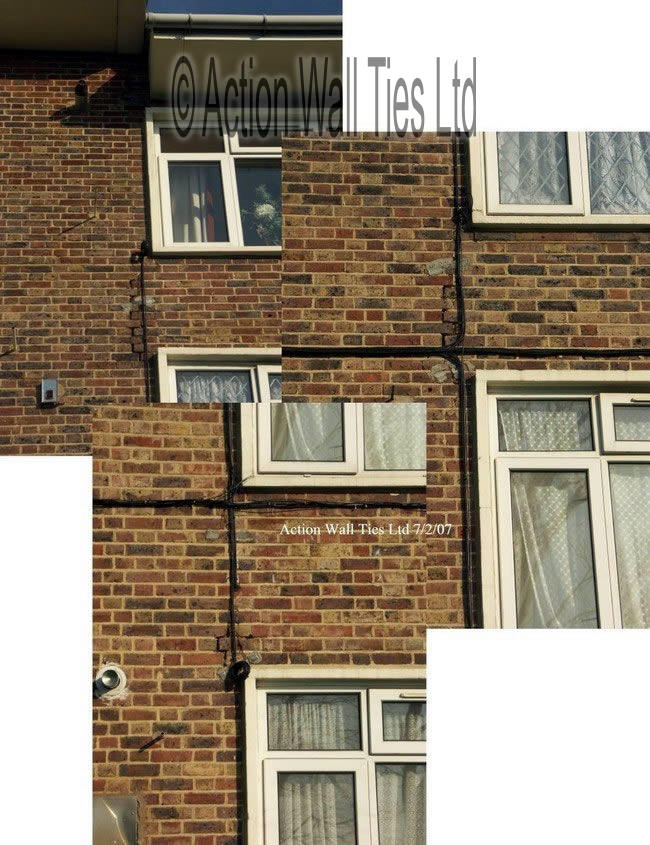

Many low rise blocks from the 60s and 70s develop defects that require concrete boot lintel repairs due to cracks, gaps and sagging brickwork above the windows. Failure to address these issues promptly can lead to dangerous, collapsing masonry as well as extensive damage to internal walls.

AWT are able to provide long term, cost-effective boot lintel repairs with minimal disruption to residents.

Concrete Boot Lintel Problems

As shown in the gallery, in the 60s and 70s, many concrete boot lintels were incorrectly fitted onto unsuitable bearing allowing the lintel to rotate and the supported brickwork to drop and crack.

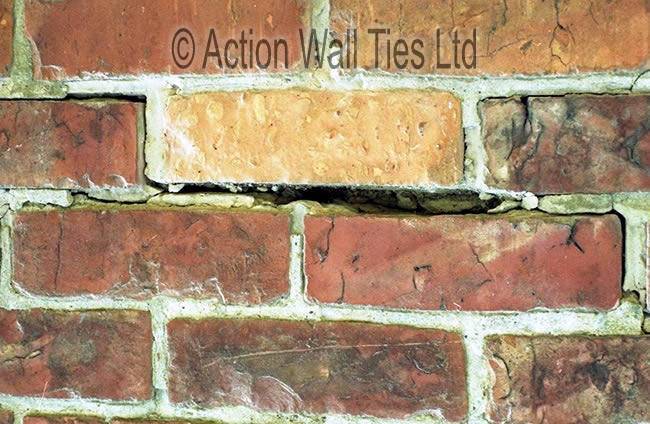

This fundamental flaw in the installation of concrete boot lintels means that the weight of the heavier brick outer skin is too great for the relatively soft and lightweight inner blocks to support. The lintel rotates, causing gaps to open up, compressing the blocks of the inner wall and causing the outer brickwork to sag.

Common symptoms of boot lintel problems:

- Cracks in the visible part of the concrete lintel

- Stepped cracks in the brickwork above windows/doors

- Dropping of the brickwork above windows/doors

- Bulging or bowing brickwork above windows/doors

- Cracks in the internal walls and ceilings above windows/doors

- Warped window/door frames making them difficult to open and close

Chris Nichols explains, “This type of lintel has no bearing onto the external brickwork the concrete lintel rarely fails. (As with any concrete the toe of a boot lintel can be affected by corroding reinforcing bars and require concrete repairs.) The boot lintel is reliant on the bearing onto the internal skin. The internal skin bearing the lintel should be of a material capable of withstanding and spreading the load (e.g. pad stone concrete blocks or engineering bricks). “

“In many cases the lintel was bedded directly onto lightweight blocks that are unable to take the imposed load and compress the outer edge of the bearing, rotating the lintel and allowing the external brickwork above to crack and drop as described in BRE Good Building Guide 1.”

Concrete Boot Lintel Repairs

Action Wall Ties provide a cost-effective, long term solution that retains the existing appearance of the brickwork with the minimum disruption to the occupants and the environment.

Action Wall Ties have developed a remedial system and methods, including specifically designed equipment, to remedy the problem of cracked concrete boot lintels. Action Wall Ties slightly anti-rotate the lintels back in place, drilling for and then resin bonding 16mm stainless steel shear pins to both end bearings. Once the resin bonded fixings are set the props are released, pre-loading the shear pins, thus reducing any further cracking.

To larger openings and with advanced movement it may be necessary to introduce two rows of twin cord reinforcement, forming a composite deep masonry beam. To the underside of the concrete toe, we drill for and inject grouted 8mm helical stainless steel pins passing into the line of the deep masonry beam to arrest any further rotation of the concrete lintel.

Action Wall Ties concrete boot lintel repair and replacement solutions are available to clients in London and the South East.

Action Wall Ties (AWT) are specialists in masonry reinforcement and repair, lintel repairs, replacing a damaged lintels, and providing professional solutions to a wide variety of structural problems. We work with home owners, London boroughs, social housing providers, architects, project managers, local authorities and insurance companies.

Contact us on 01227 721 255, or email us.