Collapsed Bay Window Restored & Reinforced

Located in Wandsworth, SW8, this Victorian/Edwardian home had clearly visible dropping and cracking masonry around the ground floor bay window.

Shortly after the initial inspection, the masonry failed and the brickwork of the bay window collapsed.

Previous attempts at repairs by re-pointing the brickwork were clearly visible but had failed to get to the root cause of the structural defect.

Rebuilding the brickwork without tackling the structural instability would lead to further problems and additional costs in the future.

AWT was able to stabilise the masonry before strengthening the structure and rebuilding the brickwork to provide a long-lasting repair.

Read our frequently asked questions about bay window structural repairs.

The Structural Problem

AWT was called in to survey this mid-terraced, period property in Greater London. The ground floor bay window masonry and brickwork arches had visible cracking, dropping and significant outward leaning. A large gap had opened up between the brickwork columns and the box sash windows. This serious lack of structural integrity was also causing the 1st floor brickwork to bulge.

The photos show the warning signs that owners of similar properties should look for that warn of serious structural defects in bay window brickwork and the risk of collapse.

Just 2 days after the initial survey, the ground floor right-hand column and arch, the front arch plus the supported external skin of brickwork collapsed. This left the brickwork above unsupported and at imminent risk of failure. Urgent action was required to avoid the collapse of the entire front elevation.

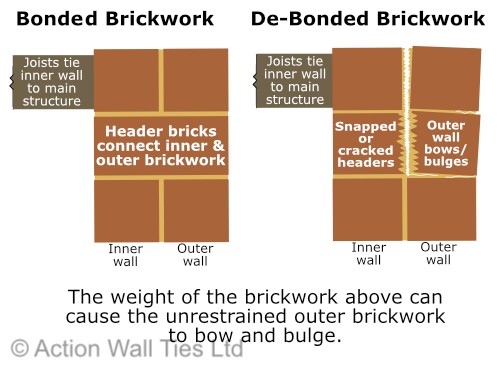

The root cause of the structural defects was a combination of aging and inadequate restraining.

The Structural Repair Solution

As is often the case, this property showed signs of previous failed attempts at repairing the defects using traditional building techniques. Re-pointing dropping and sagging brickwork provides only a temporary, cosmetic solution, it doesn’t repair the underlying structural issues.

The bay window brickwork required realignment, structural reinforcement and rebuilding all without compromising the original period features.

Temporary supports were installed to prevent further damage to the masonry. AWT’s specialist realigning cramping equipment was used to straighten the bowed brickwork.

The collapsed masonry was rebuilt with the original components where possible. Replacement bricks and mortar were colour matched. A steel spine was built into the columns during rebuilding to strengthen and restrain the brickwork.

AWT’s special diamond drilling methods were used to introduce stainless steel bed joint reinforcement to strengthen the brickwork and redistribute the weight of the brickwork above. Grouted anchor fixings, lateral restraints and resin bonded ties were also installed to reinstate the strength and uniformity of the wall. The chipped and cracked window cills were also repaired using Flexcrete.

The result was a restoration of not only the structural strength of the bay window but also the preservation of the period features.

AWT provide cost effective structural repairs for a wide range of structural issues including failing and collapsed bay windows. We operate not only in SW London but across the whole of London and the South East of England.

To book a time for one of our surveyors to visit your property or to discuss your requirements, call us today on 01227 721255, email us at enquiries@actionwallties.co.uk or use our contact form to get in touch.