Bulging End of Terrace Gable Wall

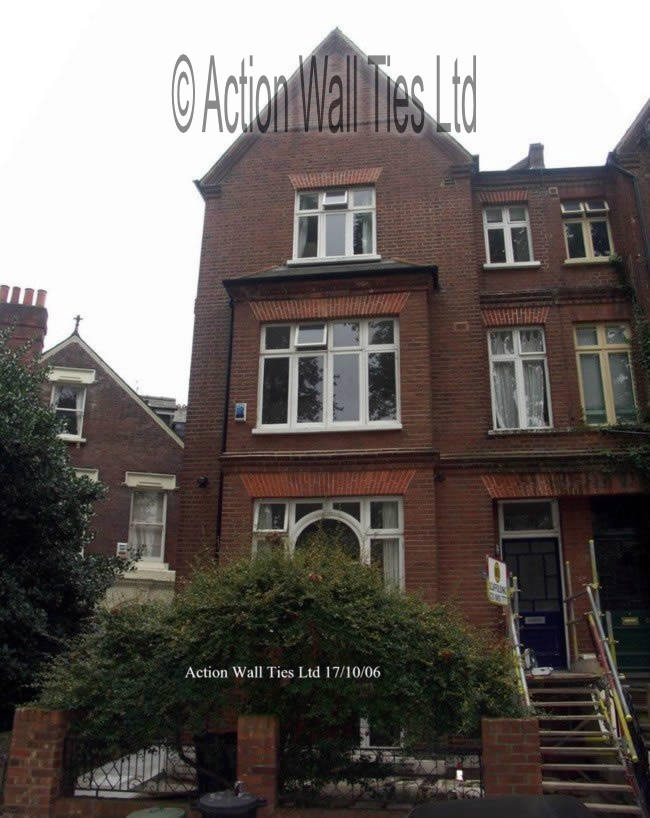

The owners of this Victorian / Edwardian end of terrace home in the Redbridge area of North East London called in AWT because of the significant outward bulging of the large gable wall of their property. There was also cracking to the internal gable end walls as well as to the internal party wall between the property and its neighbour.

The Structural Problem

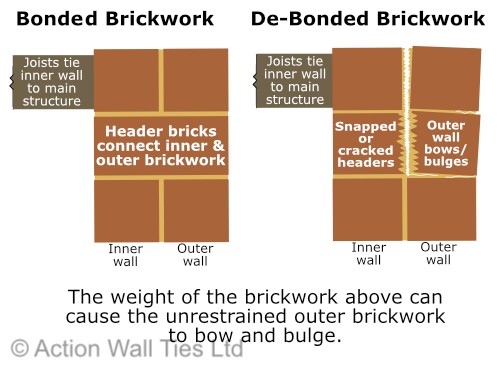

The AWT survey team visited the property in Woodford Green to identify the root cause of the visible bulging movement of the large, solid brickwork flank/gable wall. Due to aging, ineffective and inadequate restraining of the brickwork the entire gable wall was de-bonding and disconnecting with the rest of the masonry. This was leading to additional problems with the internal beams losing support.

Without structural repairs, the large gable wall would continue to pull away and eventually collapse. Traditional building methods would have required the partial deconstruction and rebuilding of the flank wall. Even then, it would not have solved the root cause of the problem – inadequate restraining of the gable wall.

The Structural Repair Solution

The team at AWT designed a structural repair package that would bring the brickwork back into alignment and add tensile strength to the structure. The specialist tools and fixings used by AWT enable them to restore the brickwork’s integrity without visible fixings or rebuilding work.

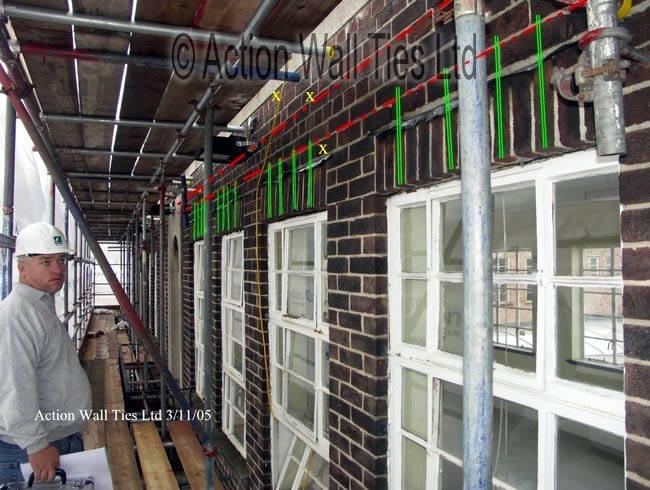

Bed joint reinforcement beaming, grout tie injection and lateral restraints were employed to reinstate the uniformity of the wall and provide restraint. The formation of continuous beams within the existing masonry redistributed the upper storey loads while at the same time assisting in restraining diagonal cracking and bulging tendencies.

A specialist drilling rig, designed by AWT, was used to drill through the brickwork at a shallow angle to maximise the number of bricks connected by each helical, grout bonded fixing. The internal timber beams were reconnected to the masonry using resin bonded stainless steel fixings.

Cracked and disturbed areas of mortar were raked out and replaced with fresh mortar that was matched for colour, texture and pointing style.

AWT provided a long term solution for the bowing gable brickwork. By targeting the repairs exactly where they were required the work was completed swiftly and with minimum inconvenience to the residents. The hidden fixings used by AWT preserved the beauty of the old yellow stock brickwork.

Action Wall Ties are structural repair contractors with the specialist skills required to reinforce and repair large areas of bowing and bulging brickwork. AWT work along with property owners, architects, project managers and local authorities on large and small projects.

AWT are available in Kent, London, Essex, Surrey and Sussex. To arrange a survey or to discuss project details, please use our contact form, email us or call us on 01227 721 255.