Bowing & Distorted 2 Storey Cavity Wall Bay Window

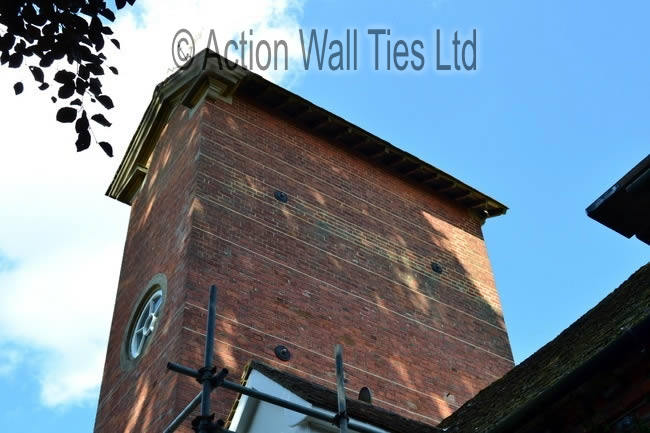

This Edwardian property in Whitstable, Kent has a cavity wall construction. It exhibited visible distortion, bowing, and cracking movement in the two-storey bay window. Without urgent structural repairs, the bay window masonry was at risk of collapse.

Methods used by traditional builders, such as repointing the brickwork or simply rebuilding the columns, cannot solve the underlying issues. AWT’s targeted structural repairs are fast, cost-effective and permanent.

Read our frequently asked questions about bay window structural repairs.

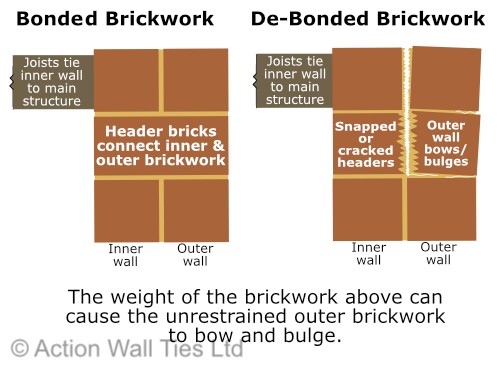

The Structural Problem

Our survey identified a combination of ageing materials, ineffective/inadequate restraining of the cavity walls and corroding mild steel arch bars as the root causes of the structural defects. Without suitable repairs, these serious structural issues would result in the collapse of the structure.

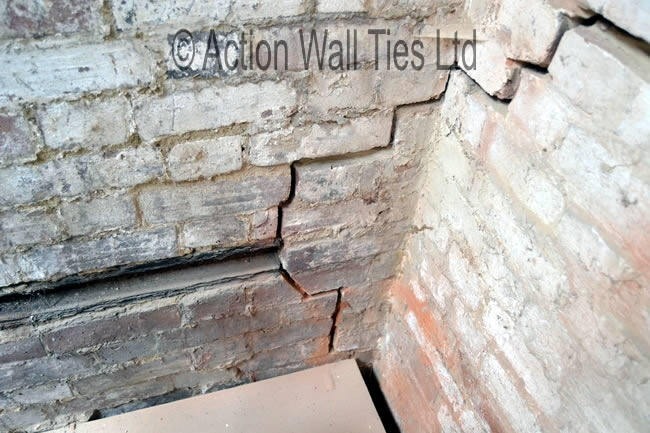

The double-height bay window has a cavity wall construction, which is less substantial than solid brickwork. The bay window brick columns are only single brick, with no additional reinforcement or fixings. The lack of strength in the bay window columns had caused significant outward bowing and distortion of the central ground and first-floor supporting columns. This, in turn, caused spreading and cracking of the brickwork arches and the brickwork above, as well as the brickwork junction of the bay with the main elevation. Inside the property, large cracks had opened up in the plaster.

The mild steel arch bars had also corroded. The ferrous oxide (rust) forming expands several times the thickness of the original metal, causing lifting/bowing of the walls and damage to internal finishes.

Get a Free Estimate

Book your no-obligation, free survey today.

In many cases AWT can provide free advice, without a site visit, based on photos of the structural faults. Send us photos of the defect using our contact form or email us.

The Structural Repair Solution

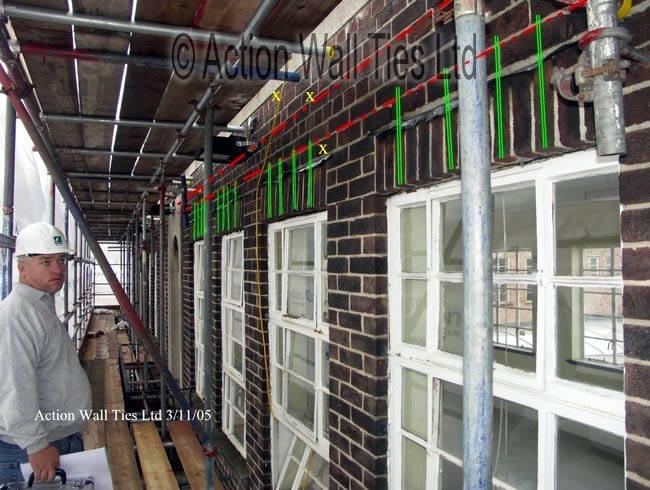

Our remediation work included reinforcing the masonry and removing the corroding mild steel arch bars. With our special techniques, there was no need to empty the rooms or remove the windows. The majority of the work is carried out from the outside of the property.

The cavity wall construction required AWT to reinforce the single brick outer skin of the brickwork. With less depth of masonry than solid brickwork, precise diamond drilling was needed. AWT used its custom designed drilling rigs to install steel fixings in the exact locations required. This provides a permanent repair without visible fixings and without losing period features.

The structural repair works included:

- Installation of temporary supports & deconstruction of the brickwork columns

- Rebuilding columns incorporating steel spines and retaining ties

- Bed Joint Reinforcement

- Removal of corroded arch bars

- Brickwork arch repair

- Diamond drilling and injecting grouted ties

- Lateral restraints

- Resin bonded ties

- Brickwork repairs

Installing fixings within the masonry to form continuous beams redistributes the upper-storey loads and restrains diagonal cracking and bulging tendencies. It also preserves the appearance of your period property and its market value.

Our skilled staff use traditional methods and the original bricks where possible. The mortar style and colour, and replacement bricks if required, are matched to the existing masonry.

We work with home owners, insurance companies, structural engineers, loss adjusters, architects and project managers to find economical and effective solutions. We operate across Kent, London and the whole South East of England.

To book a time for one of our surveyors to visit your property or to discuss your requirements, call us today on 01227 721 255, email us at enquiries@actionwallties.co.uk or use our contact form to get in touch.