Customer Stories

Learn about our previous projects, filter by property type, defect and our solution for each

Learn about our previous projects, filter by property type, defect and our solution for each

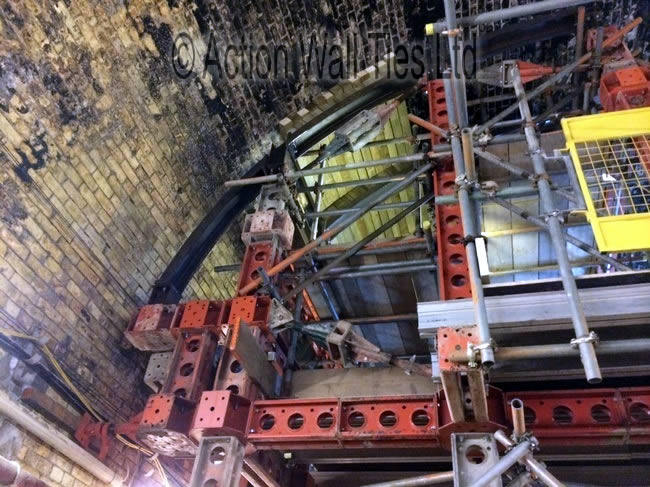

The Crossrail project was to breathe new life into the old Connaught Tunnel. It was built by the Victorians but was, at the time of this work, a disused brick-arched structure lying beneath London’s Royal Docks that survived a hit from a bomb during WW2. This was to be the only existing tunnel to be re-used for Crossrail. Works involved the widening, deepening, as well as strengthening, of the existing structure.

Action Wall Ties’ expertise and experience was sought to undertake the proposed strengthening works to the brickwork arches to the approach cutting, and the damaged area of brickwork rings that form the tunnel. This was to be carried out with the introduction of injected grout, grouted ties and pressure grouting areas where the brick work rings had separated, which was believed to be due to bomb damage.

In line with the Crossrail specification to reconnect the brickwork with the temporary supports in place we firstly drilled vertically 20mm holes 1000mm deep and injected cementitious grout, filling any contiguous voids. Once this was set we revisited the grout filled holes and re-drilled to 25mm for, and injected, cementitious grout and 16mm stainless steel bars simultaneously pinning the brickwork rings together.

After the completion of the pinning, in an attempt to fill any voids to complete the reconnection, we drilled a pattern of 16mm holes with the entrance counter drilled to receive injection packers, ready for the pressure grouting injection. With the pre-batched TamCrete MFC grout mixed and holes flushed with water we injected the grout up to 1 bar over injection pressure, until either hydraulic lock or venting grout from adjacent holes is attained.

Finally, AWT made good the entrance holes with concrete repair mortar.

AWT can provide cost effective structural repairs for a wide range of public sector and infrastructure projects. We operate not only in London but across the whole of the South East of England. We have many years of experience working on large projects, liaising with structural engineers and local authorities.

Contact AWT today to book a survey with one of our experienced team of structural repair specialists. Contact us on 01227 721 255, or email us.

Our specialist structural repair contractors will be happy to help provide a comprehensive and permanent repair to your structural problems.